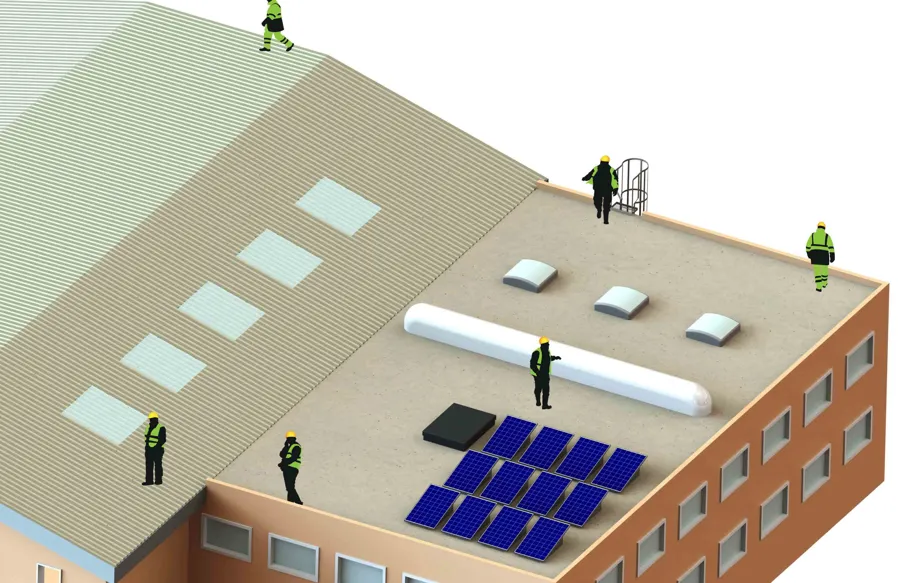

Cutting-edge safety systems

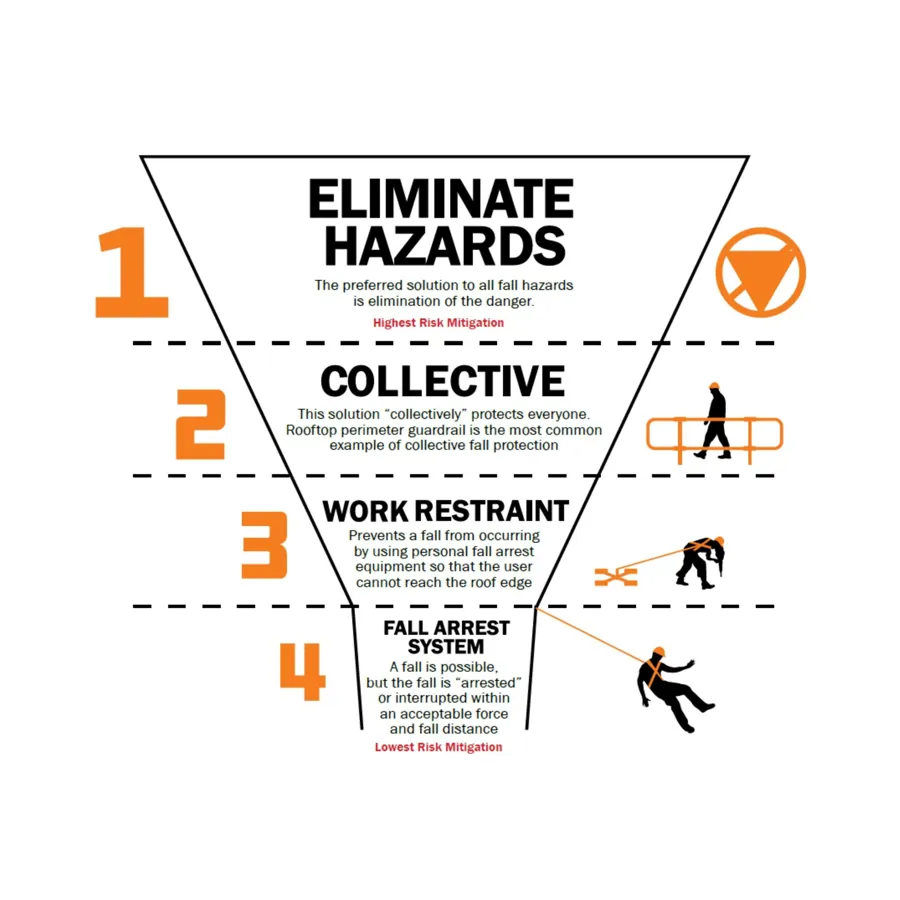

The edge of the roof is the most visible hazard, and typically the hazard most people want to protect first. Roofs need to be accessed throughout the year for maintenance and repair purposes so it’s essential to make sure workers are protected from slips, trips and falls from the roof edge. UK, EU and OSHA regulations require that if a worker can be exposed to a fall, then they must be protected. Our safety specialists are ready to ensure the safety of your team from any unprotected roof edge.